Orders & Worldwide

Orders & Worldwide

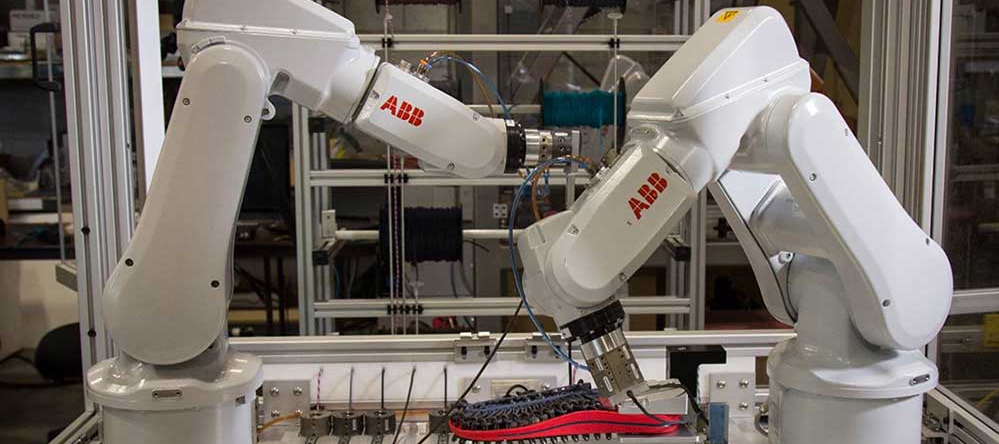

ABB robots are world’s most popular industrial robots. ABB Robotics, Sweden produces an amplified variety of Articulated Robots for hundreds of thousands of manufacturing industry applications. ABB also keeps as a precautionary measure a large inventory of new spare-parts of ABB robots.

ABB Sweden produces its robots in different shapes & sizes in order for the most demanding applications. The Most common is the larger ABB robot like the ABB 6640 which is used for spot welding application in automobile plants & smaller welding robots for welding applications. ABB Robotics made models are capable of Dispensing tasks as & material removal robots. The ABB 4600 robot wrist can be fitted with a spindle to handle Deburring applications.

ABB produces various types of robots but the main focus is on Articulated Robots also known as Industrial Robots. The ABB six axis robots range in Working Payload of 3 Kg’s IRB 120 to the giant 1000 Kg’s IRB 8700. ABB also has robots in small payload e.g., SCARA Robots used in Palletizing Automation tasks as well as parallel also known as delta robots for sorting tasks. Very Advanced collaborative robots are also available which are used for Robotic painting jobs. ABB Small work envelope robots also available as well as long reach robots capable for over 12 feet’s reaching capability. ABB Robotics have also options available for use in clean-room & Robotic Foundry applications.

Similar to other famous robots manufacturers ABB robots price is variable according to their specifications range for an older model to a larger latest model unit. ABB Robots with a Variable payload Capacity between 150 to 340 Kg’s Price/Cost is roundabout US$15,000 which are IRC5 controlled versatile models. These IRC5 controlled Industrial robots are more known in the used market due to their heavy use in Automobiles Production. Most of the used ABB robots are available in the market for below $25,000 including newest models.

Purchasing a slightly used ABB robot is another cost effective way. As there are dozens of ABB robots in the market for sale with a wide options of sizes, styles & payloads. ABB industrial robots are also capable of automated MIG welding & Robotic Laser Welding. So purchasing an ABB industrial robot is an easy target as ABB has a large variety of multi faced robots. While most of ABB robots are IRC5 Controlled models, while other are older models with the S4C+ Controller. So it means that used ABB industrial robots can quickly & cost effectively workout most of Robotic Applications.

As ABB robots are considered as Tip Of The Iceberg amongst the most dependable industrial robots in the world. However to

keep ABB robots which are in action across hundreds of industries for Industrial Automation Tasks it needs full physical attentionSo ABB Industrial robot needs to be periodically inspected. In order to maximize the benefits of ABB Robots they must remain in their utmost condition. ABB Robots should be in Top notch condition while they operate for maximum productivity while they are exposed to most hazardous surroundings during Industrial Production.

Maintenance for ABB Industrial robots can be like Preventative Maintenance. The Preventative maintenance is the most common method which in use for the maintenance & care of an ABB industrial robot. Preventative maintenance is a set of pre-calculated tasks that are performed at scheduled timing based upon either a calendar time or Robot total working hours. Preventative maintenance is normally carried out/done at once a year or at every Max. 4,000 hours of robot run time. Tb hat’s why conducting regular maintenance at predefined intervals fully ensures an ABB industrial robot continuous functionality like a new robot thus extending its life time.

When carrying a Preventative Maintenance Routine on an ABB Industrial Robot, the following 7 actions are highly recommended.

So proper maintenance of ABB industrial robot will help avoiding costly repairs, productions disruptions & complex operational problems.

Till now speaking of robotic spares inrobots.shop is the most Diversified Online Platform for ABB Industrial Robots spare-parts. Whether you need almost new spare-part or slightly used or fully refurbished spare-parts inrobots.shop is your One-Stop online solution for all your spare-parts needs.

Inrobots.shop offers a variety of services you have ever thought in your perspective. Backed by years of professional experience in industrial robots spare-parts one hasn’t to search here & there for even for special services like Free Customer Advice on spare-parts selection.

ABB robots especially ABB Industrial Robots have the most complex & complicated parts which often get often partially or fully damaged due to heavy & continuous use e.g., a Teach Pendant which is used for ABB robot programming or testing when a robot is in Teach Mode. Servo Motors also play a very important part as in an ABB industrial robot the number of servo motors is at-least 6 & maximum 9 in a full industrial robot. Sometimes a servo motor gets burnt out due to continuous excessive use.

Servo Motor Drive is a Standalone Module for exclusive control of servo motors. A servo motor drive can control more than one motor at the same time. ABB Robotic Control Cabinet is for Exclusive control of robot during its operation. So whatever is the need inrobots.shop is there to serve its cliental anywhere, everywhere & anytime in the world with best warranty one can expect from a spare-parts services provider with extensive warranty & free spare-parts advice on how & which spare-parts to look for & purchase with after sales warranty money can buy.

Inrobots.shop is the best online under one roof platform for such persons/companies/dealers that are looking for quality ABB Industrial Robotics spare-parts online. So get connected online to inrobots.shop for all their different needs. They won’t be disappointed by Extended Style services given by inrobots.shop.

As inrobots.shop has the largest inventory in one pace for all types of robots but their specialty is in industrial robots spares. So rest assured you are going to have a lifelong best experience after dealing in spare-parts. So try inrobots.shop for all yours spare-parts needs for having the best of the best spare-parts deal, free services & warranty you haven’t seen before.

Leave a comment