Orders & Worldwide

Orders & Worldwide

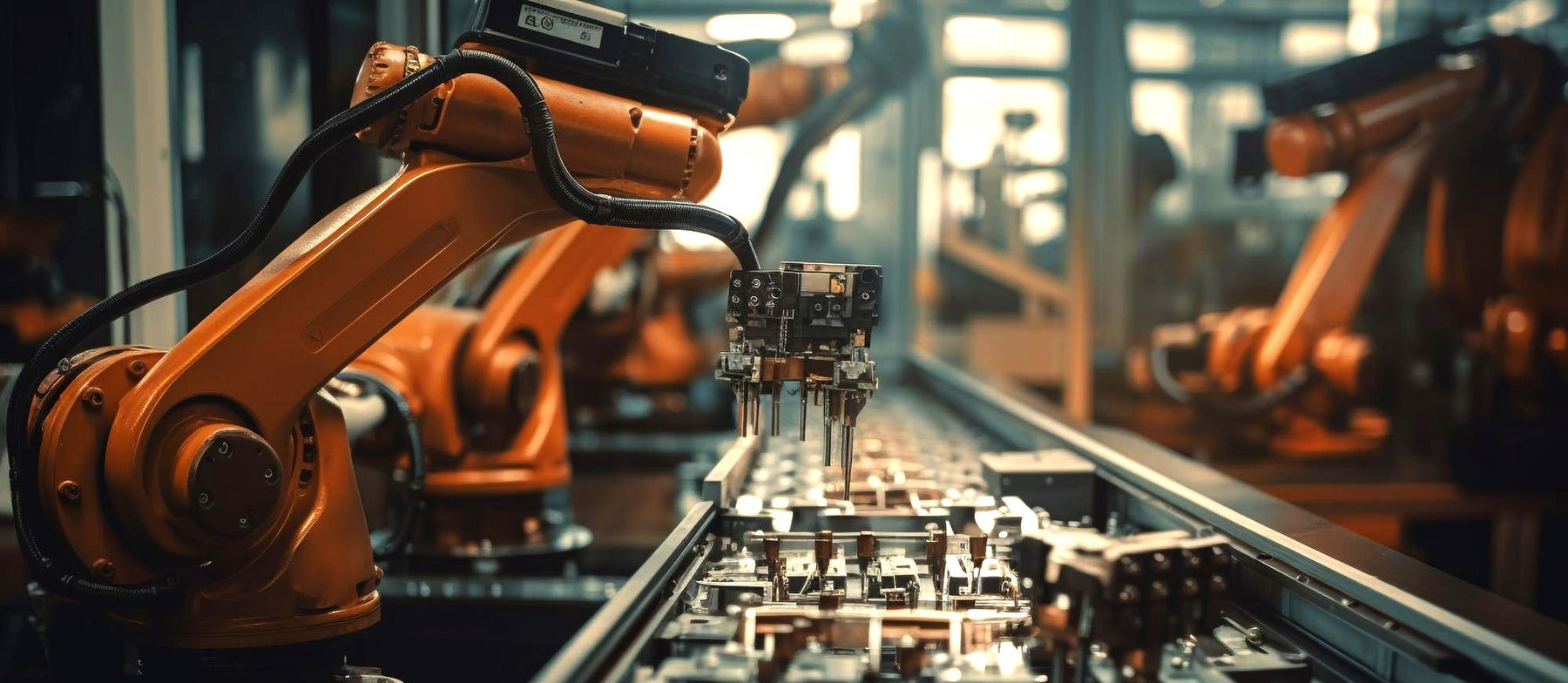

A Robotic Servo Motor is Specialized Electromechanical Device which acts as an Actuator of an Industrial Robot Arm. It working is to convert electrical energy in mechanical energy thus by moving or rotating an object. A Servo Motor main parts are the Electric Motor, a Control circuit i.e., a PCB & a Position/Error Sensing miniature part e.g., an Encoder or High grade Sensor or Sensors. That’s how these three Multi components work together in real-time for the exact movement of an Industrial Robot Arm accordingly to the output sensor signals from a Robot Controller Box, a Standalone Drive or a PLC.

As now we know that a Standard Servo Motor System is comprised of three main parts a precision control system i.e., a dedicated drive, a robotic servo motor. The 3rd part is a sensor’s based motion, position, load, error detection & feedback system inside the Servo Motor.

It should be noted that a robotic motor servo system works on the principle of Pulse Width Modulation (PWM) Signal. The servo motor drive which is a standalone module & is exclusively for one or more than one robotic servo motor control sends signal to Sensor’s Based System located

inside servo motor the type, pulse duration & modulation of that signal initiates the servo motor to “Rotate Clockwise/Anticlockwise, Accelerate, Decelerate, Stop, Start or keep Motion & Rotation at a specific Power & Torque” as specified by the servo motor drive.

Servos Motors are due to the above reason used in robots arms as they give precision based accurate & real-time movements. A Servo motor has a feedback system that can easily & accurately align the position of an Industrial Robot Arm and adjust accordingly with the task, load & work requirements. This helps a robot to execute Repetitive Tasks precisely drilling, welding, painting e.t.c,.

Apart from that Servo Motor Systems can be programmed to turn off, on, slow down instantly which makes them a good choice for agility & speed based tasks such as pick-and-place operations also called Single-line Palletizing, Multi-line Palletizing e.t.c,.

Interestingly, robotic servo motors consume very less energy as compared to ordinary motors, making them extra efficient for use with robotic arms without any draining of precious resources &/or increased operating costs.

Last but not the least most of servo motors are small in size which makes them 1st class choice to integrate into industrial robotic arms allowing for more accurate & precise movements which is specially useful for such tasks

Which require precise & delicate manipulation i.e., assembling very small parts.

A wide range of Servo motors are relatively inexpensive when compared to ordinary motors such as stepper or brushless DC motors types. They are very cost-effective so that they can be used in a wide range of robotics applications.

Robotic Servo Motors are able to produce desired Torque in comparison to their weight & size, making them best for use in robots arms where powerful motion is wanted. Such power also ensures drastic movements & to control objects with accuracy.

Other motor technologies require large &/or heavy energy input but robotic servo motors need Nominal Energy input to Work with full capacity making them very flexible & logical in energy consumption. They can be programmed easily & quickly via a Teach Pendant for a wide array of robotic movements.

Industrial Robotic Servo Motors are designed in such a manner that they can withstand long-term use and have a long lifespan, so they can be used for a long term without any significant repairs or maintenance. That’s they are ideal for industrial robotics applications where accuracy is a must as well as robot downtime must be minimum.

Servo motors come in different & variable sizes from the tiny small-servos to the largest industrial-class servo motors as they cover a range of robotic applications, such as building miniature robots or powering large industrial systems. This specialty makes them one of the most modern & state of the art electric motor technologies.

Servo motors are designed to be user-friendly and easy to install which makes the ideal choice for Industrial Robotics Applications. They can be easily programmed via a Teach Pendant by Professionals with less technical expertise.

Servo motors are so easily available from different manufacturers that finding their compatible components &/or spare-parts globally is trouble-free so any Industrial Robotics Projects is easily handled.

Servo motors gross weight is light as compared to ordinary motors thus they are an ideal Electromechanical Gadget for Industrial Robotics Automation That’s nowadays industrial robots have reduced weight & High mobility & Work precision.

The use of Servo Motor robotic Arm is day by day becoming popular and the technology is rapidly advancing & going towards Technological Evolution. Servo motors are the most modern & indispensable electromechanical item.

Today’s industrial robotic Servo motors are more precise in working than conventional DC motors & more compact in size, more intelligent in working, more aggressive to input signal response in very less time. They have High Power & Torque due to their most Standardized & Modernized working mechanism. With the most modern software’s & programming languages coming into the hands of professionals & technicians robotic servo motors are becoming easy to operate even by the amateurs.

At the end the Essence of all the above discussion is that industrial robot associated servo motors are most energy efficient and dependable when compared with other types of traditional motors which were many years back used for robotics tasks. Thus the use of industrial robotic servo motors in Industrial Robotic Arm Assembly is expected to grow with a very fast pace in the coming years due to their versatility & adoptability with time (due to the increased Sophistication in Software’s). Because it’s The software’s that Are Running Precision or Heavy Hardware’s.

| SGMGH-13DCA-YG15-1 | Yaskawa Motoman AC Servo Motor |

| SGMJV-06A3A61 | Yaskawa Motoman AC Servo Motor |

| SGMGH-09DCA-YG24 | Yaskawa Motoman AC Servo Motor |

| SGMRV-13ANA-YR11 | YASKAWA Motoman Servo Motor |

| 3HAC17484-8/08 | ABB AC Servo Motor |

| 3HAC021456-001/04 | ABB AC Servo Motor |

| MUGU-518045 | ABB MU100 Motor Unit & Gear Unit |

| 3HAC025724-001/03 | ABB AC Servo Motor |

| A06B-0116-B203 | FANUC AC Servo Motor |

| A06B-0115-B855 | FANUC AC Servo Motor |

| A06B-0223-B000 | FANUC AC Servo Motor |

| A06B-0031-B175 | FANUC AC Servo Motor |

Leave a comment